Troubleshooting Common Issues with Industrial Scales and How to Fix Them

Troubleshooting Common Issues with Industrial Scales and How to Fix Them

Blog Article

Why to Select Industrial Scales for Accurate Weight Measurement in Various Industries

In a period where precision is vital, the option of commercial scales for precise weight dimension plays a crucial function throughout diverse sectors. These scales not just boost operational effectiveness yet additionally make sure compliance with regulative criteria, impacting everything from production to delivery.

Significance of Accurate Weight Measurement

In the realm of industrial operations, the relevance of precise weight measurement can not be overemphasized. Exact weight dimension is foundational throughout numerous markets, influencing both operational effectiveness and product high quality - Industrial Scales. It acts as a crucial aspect in stock monitoring, guaranteeing that materials are adequately accounted for, thereby reducing waste and decreasing costs

In manufacturing, exact weight dimension straight influences manufacturing procedures. Abnormalities in weight can cause ineffective products or too much source appropriation, influencing general success. Furthermore, in sectors such as drugs and food production, adherence to strict weight specifications is essential for governing compliance and consumer safety.

Moreover, exact weight dimensions help with effective logistics and supply chain administration. Appropriately evaluated shipments make certain that transportation costs are maximized and that inventory degrees are preserved accurately, therefore protecting against supply scarcities or overstock scenarios.

Types of Industrial Scales

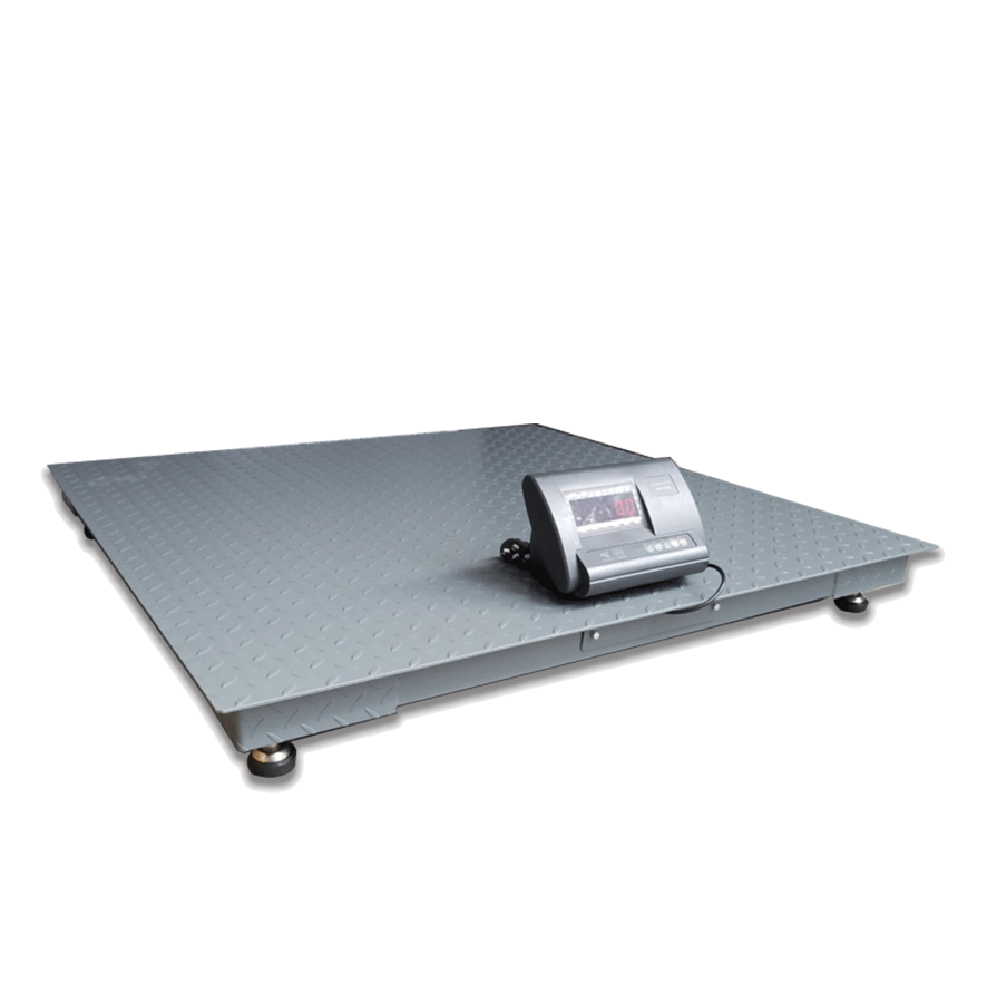

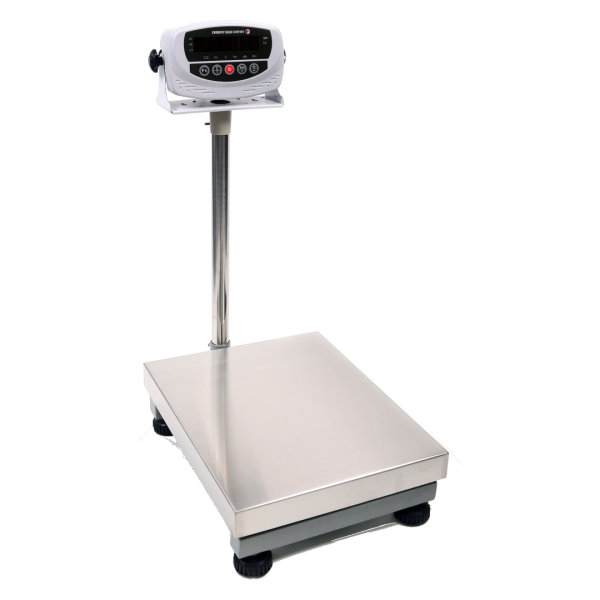

A wide array of industrial scales are readily available, each developed to fulfill certain measurement requires across varied sectors. Usual kinds consist of floor ranges, which are robust and ideal for considering huge items or pallets in warehouses and warehouse. Bench scales are smaller sized and excellent for lighter materials, typically utilized in retail settings or manufacturing for precise part control.

Another classification is mobile scales, which use the flexibility to be moved conveniently around job sites, making them excellent for field procedures or temporary arrangements. Accuracy scales, on the various other hand, are developed for high precision and are regularly made use of in labs and quality assurance environments.

Load cells are vital components in various industrial ranges, converting force into an electrical signal for exact analyses. Additionally, vehicle scales offer the ways to consider hefty vehicles and their loads, guaranteeing conformity with laws and enhancing logistics.

Finally, checkweighers immediately contrast the weight of items versus preset restrictions, improving quality control in production lines (Industrial Scales). Each type of industrial range serves an unique function, catering to the specific needs of sectors such as production, logistics, food handling, and drugs

Advantages of Utilizing Industrial Scales

Continually making use of commercial scales supplies substantial benefits throughout different industries. One of the primary advantages is improved accuracy in weight measurement, which is essential for maintaining quality criteria and regulatory compliance. Accurate dimensions protect against costly mistakes in shipping, supply, and manufacturing monitoring, inevitably causing enhanced functional performance.

Additionally, industrial ranges are created for durability and effectiveness, enabling them to stand up to severe environments commonly discovered in production and warehousing. This durability ensures a lengthy life expectancy, lowering the need for frequent substitutes and maintenance expenses.

In addition, using industrial scales improves security and lessens waste. By guaranteeing that products are evaluated precisely, business can prevent straining lorries, which can bring about crashes and fines.

Applications Across Various Industries

Industrial ranges play a pivotal duty in numerous fields, consisting of production, logistics, food handling, and drugs. In manufacturing, these scales are important for guaranteeing that basic materials are measured accurately, thereby keeping item high quality and consistency (Industrial Scales). Precision in weight dimension straight influences production efficiency and cost monitoring

In logistics, commercial scales assist in the accurate considering of deliveries, which is important for adhering to optimizing and delivering regulations freight costs. Exact weight data helps simplify operations and improves supply chain management.

The food handling sector counts heavily on industrial scales for compliance with health and wellness laws. They are utilized to consider ingredients precisely, ensuring that solutions satisfy both top quality requirements and legal needs. This is crucial not only for customer security yet likewise for keeping brand stability.

Pharmaceutical companies use industrial ranges to guarantee exact dosages in medication manufacturing, where even the least discrepancy i thought about this can have substantial consequences. Conformity with stringent regulative criteria makes precise weight measurement essential in this industry.

When Choosing Scales,## Variables to Consider.

Choosing the right range for specific applications needs mindful factor to consider of a number of aspects. The capacity of the scale is vital; it has to accommodate the maximum weight of the items being measured without exceeding its limitations. In addition, the readability, or tiniest increment the scale can accurately display, is important for precision, especially in markets where weight disparities can cause substantial monetary losses or safety and security problems.

Ecological problems additionally play a significant duty in scale option. For instance, scales made use of in moist or harsh environments might need specific materials to guarantee resilience. Likewise, transportability might be crucial in certain applications, necessitating battery-operated and lightweight versions.

Verdict

In conclusion, the selection of commercial ranges is critical for guaranteeing accurate weight dimension across diverse sectors. Hence, spending in top notch industrial scales is crucial for companies intending to make the most of and maintain high criteria earnings.

Report this page